Energy & Resources

Achieving energy conservation, cost reduction with efficiency gains, intelligent manufacturing, and enhanced managerial excellence

Raw-material volatility & Technological disruption in the Net-Zero era

Wild swings in commodity prices, unprecedented decarbonisation pressure and the rapid iteration of clean technologies force energy and resources companies to master three challenges at once: stabilising costs, shrinking their carbon footprint and accelerating digital-intelligence upgrades

Constrained raw-material supply

Effective commodity-price management is critical to sustaining profitability

Environmental and decarbonisation pressures

Stringent regulations and net-zero targets are propelling the energy mix from high-carbon to low-carbon sources

Technology and product innovation

In the digital era, continuous product innovation drives competitive advantage and higher margins, while next-generation processes underpin manufacturing excellence

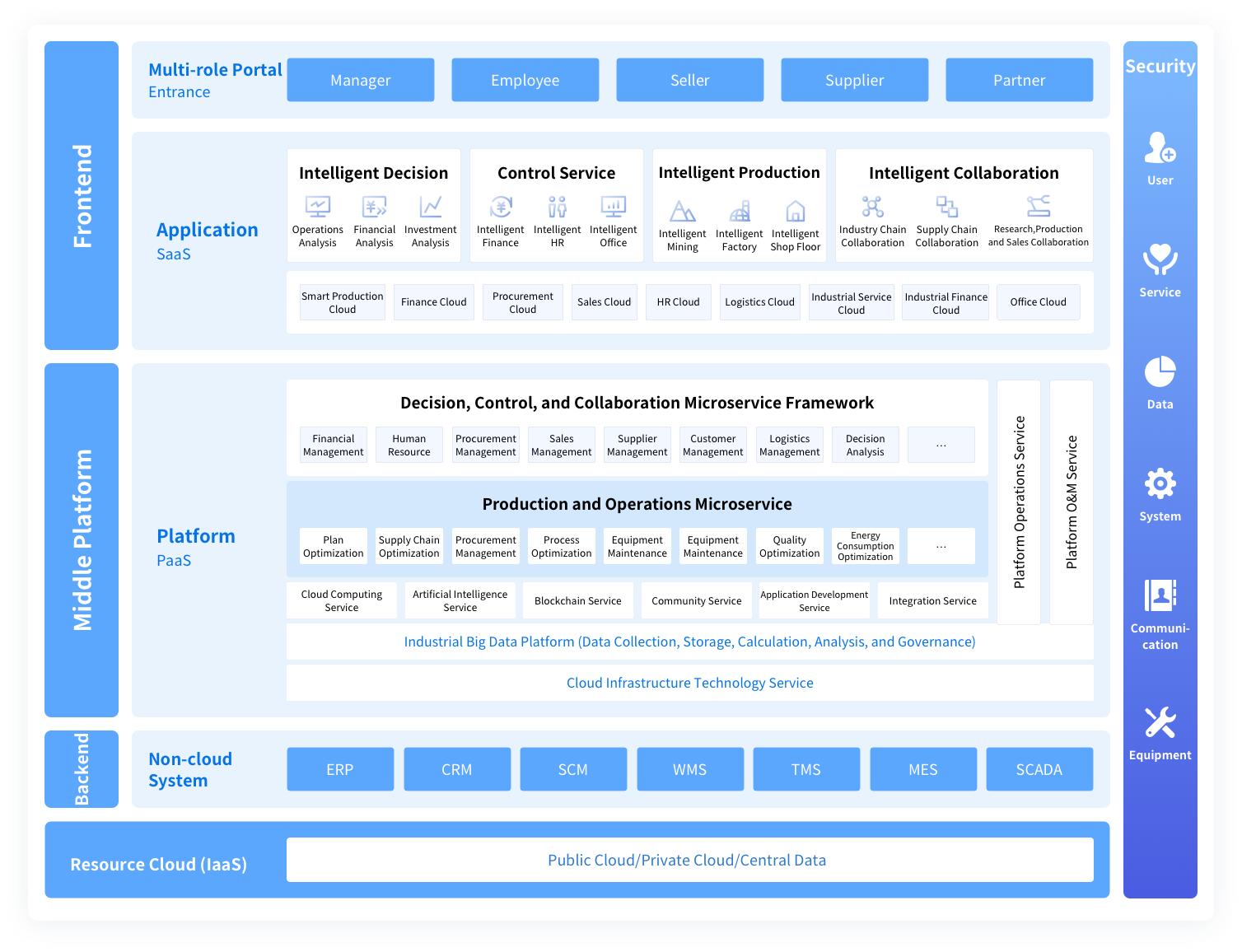

Energy & Resources solutions from Kingdee and our partners

Solutions that address specific industry needs help you achieve cost-effective transformation and sustainable growth

Real-time design-to-manufacturing sync solution

Digitize and visualize R&D, creating a data-driven, interconnected environment where design and change data sync in real time with production, supply chain, and finance—fully supporting manufacturing and supply-chain management

Order-driven multi-tier planning solution

A digital planning framework links sales, MPS, and MRP into an order-driven, multi-level planning system

Project-centric ETO execution solution

Manage people, capital, materials, and every production, supply, sales, and service activity around a single project thread. Gain precise control over resources, schedules, costs, quality, and risks to achieve full project-lifecycle governance

Product service & Operations

Provide a unified service model that spans proactive prevention—through preventive and predictive maintenance—in-process control via an end-to-end closed loop, and post-event repair. This creates a continuous cycle of service planning, operation, and optimisation

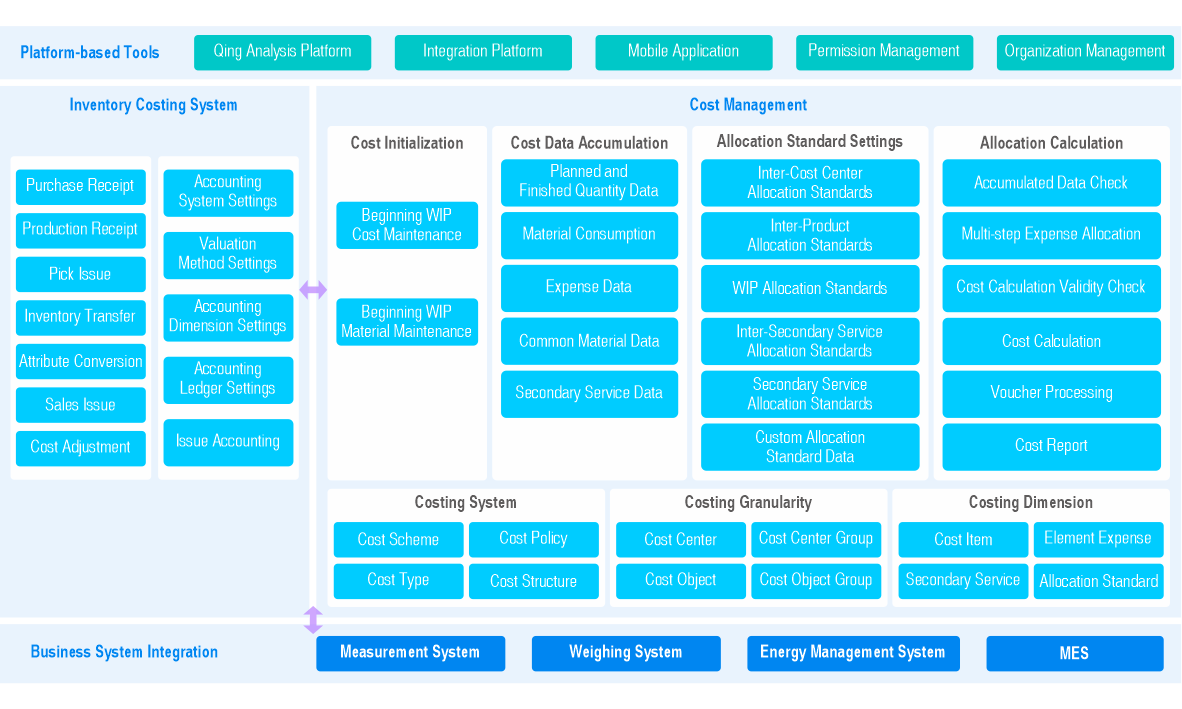

Hybrid cost modeling for process-specific accuracy

See what’s new of automotive solutions

Frequently asked questions

Absolutely. Kingdee allows you to build demand-supply models across material, capacity, priority, quantity, and time dimensions. You can further define calculation strategies using manufacturing policies, planning scope, material-planning models, material backflush models, batch-calculation models, and optimization-objective models.

Ready to get your tailored solution?

Talk to our industry experts right now

+853 2853 3813

+853 2853 3813